The best solutions for Big-Bag Filling...

Your Raw Materials, Semi-finished Products, or Final Do you want to fill your products in Big-Bags? Tnm Industrial offers various sizes for many fluid products. Big-Bag filling systems in different sizes and capacities. Our Big-Bag filling machines; granular and fluid powder It can be used without any problem for your products. For your powder products, the Big-Bag filling machine can be equipped with an optional Local Dust Filter. In this way, the dust that will occur during operation, depending on the product type, will be prevented and the hygiene of the operation and the health of the employees will be kept stable. With our help, your transactions will definitely run smoothly. Browse our services online.

It is completely made of steel construction and configured with the latest technology equipment. It is extremely easy to use with the operator panel with user-friendly interface. Our Big-Bag filling machines can be mounted on the optional machine and You can equip these silos with Mechanical or pneumatic Pneumatic Conveying systems to fill them with Mechanical or pneumatic Pneumatic Conveying systems.

Our machines are used for filling the following products: ◆ Plastic granules; (PP/PE /LDPE/HDPE) ◆ Granulated Raw Materials of All Kinds ◆ Granulated Sugar ◆ Powder component products ◆ Sesame ◆ Pulses; Rice, Lentils, Bulgur, Beans, Chickpeas, Broad Beans

Food Industry Food production is one of the world's largest, most diverse and most important industries. Bulk product transportation has become very important in recent years. Big-Bag product supply is often preferred because it meets the high hygiene standards of the food industry and provides efficient material transfer. A wide range of food products such as sugar, rice, corn, spices, cereals, flour and animal feed can be transported using Big-Bag. Chemical Industry The chemical and petrochemical industry is one of the sectors that heavily uses Big-Bag bags to transfer chemicals. The use of polymer materials is in vogue, leading petrochemical industries to process high volumes of raw materials (monomers). Precise Big-Bag filling machines are needed during the transportation of bulk materials in this sector.

Plastic and Polymer Industry The plastics and polymer industries produce a large number of various raw materials and transports it. Transportation, loading and unloading costs of granular and powder products most suitable to be transported in Big-Bag bags to minimize is one of the options. In the plastics industry, products are very valuable for Big-Bag bag filling must be effortless and fast. Our machine has been specially developed for these conditions.

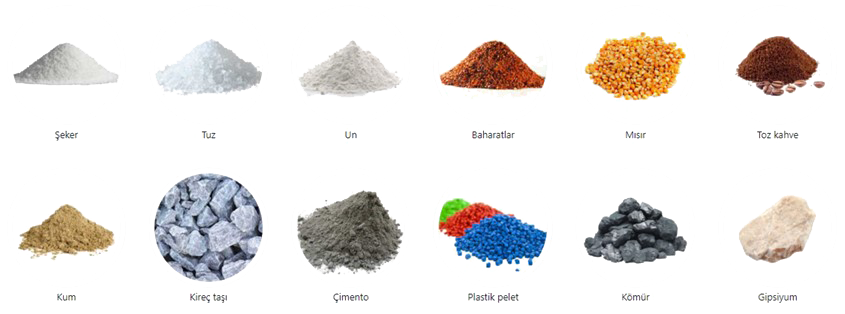

Bulk Raw Material Filling Dry material shipments in bulk raw material transportation are most easily made with Big-Bag bags. The machine does not pose any risk to the filled product. It does not have any attachment or apparatus that will disrupt the structure of the product. All surfaces that the product comes into contact with are made of Stainless Steel. Thus, the risk of damage or contamination of the bulk material is prevented. Examples of materials transferred with Big-Bag bags are sugar, spices, salt, flour, corn, popcorn, coffee beans, sand, limestone, cement, coal, gypsum, plastic pellets, powdered plastic, calcium carbonate.

We can offer different solutions with configurations suitable for your system and process.

Our machines are fully configurable and adaptable according to the customer's wishes and the operation of the process. For possibilities, please contact us for Various Variations. ◆ Do you want to buy a 1000 kg or 1500 kg Big-Bag Filling machine? ◆ Do you want to fill your products into Big-Bags untouched? ◆ Would you like to see on your PC screen or Mobile Phone how many Big-Bags were filled in a working day and how many kilograms of product were filled in each Big-Bag? ◆ Would you like the products in your warehouses to be automatically transferred to your Big-Bag Filling machines? ◆ Do you want to automatically receive and stock your wide variety of products in different warehouses and transfer them from these warehouses to your Big-Bag Filling machines? ◆ Have you seen our Modular Galvanized Silos that we can offer you for stocking? ◆ Would you like to see the amount of the product you are stocking in the silo and how many kilograms of product are placed in the silo on your computer screen? ◆ Do you need a 25 kg palletized bag unloading machine to unload palletized products in 25 kg bags and automatically fill them into Big-Bags? ◆ Would you like to report how many pallets of raw materials the Bag Unloader unloads in one day? ◆ Do you need a homogeneous dosing station, no matter how many components you have? ◆ Do you want to dose and mix products with different ingredients that you store? ◆ Would you like us to set up your system to work 24 HOURS a day? ◆ "Human beings make the most mistakes." - "It is human to make mistakes." Do you want to get rid of these mottoes, these clichés? ◆ Would you like to monitor and control your system with your mobile phone by providing remote access while your system is running? ◆ PLEASE contact our experts so that we can offer you the 100% Correct Configurations.

BIG-BAG FILLING MACHINE

◆ Big-Bag Filling Machine is designed to be operated in heavy industrial conditions. ◆ The granular or powdered products you produce can be bagged as Big-Bag. ◆ The machine has an extremely rigid body. ◆ Pnömatik asansör, tartım ünitesi, Dolum Klepesi, Torba Sarsma Ünitesi ve kontrol panosundan meydana gelmektedir. ◆ Weighing system; With stainless steel loadcell, it can fill up to 1 kg - 2.000 kg at the desired capacity. The machine is a Big-Bag Filling System with automatic weighing. The system has the ability to fill with a capacity of 20 t/s and 1/1000 precision. ◆ The system is configured with highly sophisticated software. Many setting parameters are available on the operator panel. The machine can be easily adapted to different bag types. ◆ Many steps such as tolerance values of the products to be filled, filling time, filling min. and max. kg. values, bag shaking times, etc. can be set on the operator panel. ◆ During filling, the Big-Bag bag is suspended by means of a pneumatic piston and the product is filled to all points of the bag. After the filling is finished, the carrier table is lifted up thanks to the pneumatic bellows and the vibration motors work. In this way, the bottom of the bag is completely flattened and stable ground pressure is ensured. ◆ In this way, problems such as tipping and tilting, which are frequently seen in Big-Bag Transports, are prevented. ◆ It is designed to be used in fully industrial and heavy conditions. Thanks to the pneumatic system, the filled product is filled homogeneously in all corners of the bag. After filling, Big-Bag can be easily transferred thanks to the euro pallet design. ◆ It is a system without space and height problems. Thanks to the control panel on it, daily, weekly and monthly weighing information can be obtained. ◆ All this information can be saved on a USB disk or transmit weight information to systems such as MRP, SAP via ethernet. ◆ If needed, it can be integrated with the product filling bunker and Vertical Elevator. ◆ Powder and Granules are designed for use in sectors such as Food products, Agricultural products, Pulses and Petrochemicals. ◆ Thanks to our Local Filters that you can optionally purchase, the dust generated during filling is absorbed. Our filters have the ability to electronically clean the bags automatically with compressed air in case of contamination. ◆ Field assembly is assembled in short periods of time without interfering with operational activities. ◆ Assembly is completed between 1-2 Days / Machine. ◆ The availability of stock capability meets the urgent needs of businesses in a timely manner.