The best solutions for your bag emptying problems

Food Industry Are you interested in a bag emptying machine for food products? Tnm Industrial offers various bag emptying machines and Storage systems for granular products, Powdered products and various food products. With our help, your operations will surely run smoothly. Check out our services online.

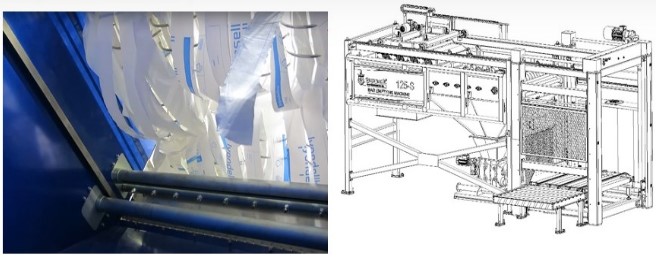

With our fully automatic Bag Unloading Machines, 25 or 50kg bags containing granules, beans, sugar or powdered food products can be emptied into the product hopper. Pallets can be fed into the machine manually or automatically. The capacity varies according to the selected bag emptying model or the product to be emptied, the capacity range is between 10 and 30 tons per hour. Once a pallet is placed in the machine, the machine will transport the pallet upwards to a shuttle with integrated grippers. The integrated grippers will grab a layer of the pallet and take it to the unloading process. Here the shuttle will drive the bags over rotating blades and a unique shaker system. Our empty percentage is over 99.98%!

Our Projects

Would you like to see what kind of projects we carry out with our other products in addition to the bag unloader? We are working to make your facility completely suitable for your Process. We direct your process with high technology, low maintenance, low energy consuming equipment.

Our Production Portfolio consists of the following components;

◆ Dosing Machine ◆ Base Model Bag Unloading Machine (125S) ◆ Standard Bag Unloading Machine (125M) ◆ Pallet Conveyor Bag Unloading Machine (125T) ◆ Bag Unloading Machine for Big-Bag Filling (125B) ◆ Multicomponent Raw Material Dosing Units ◆ Micro Dosing Stations ◆ Pneumatic Raw Material Handling and Storage Systems ◆ Mechanical System Raw Material Handling and Storage Systems ◆ (Belt Conveyor, Screw, Vertical Elevator)

Bag Unloading Machine Capacity

Standard Bag Unloading Machine Capacity: 500 - 700 bags/hour (12.5 - 17.5 tons) Bag Emptying Percentage: 99.95

Note Optional add-ons for the machine; Add-ons such as Short or Long Pallet Stacker, Empty pallet magazine do not affect the capacity.

Torba Boşaltma Makinası Modelleri aşağıdaki seçenekler ile donatılabilir:

• Base Model Bag Unloading Machine (No Pallet Feeding Unit) • Standard Bag Unloading Machine (Conveyor-fed with short pallet stacker) • Bag Unloading Machine with Pallet Stacker • Empty Pallet Magazine (Empty Pallet Vertical Stacking Unit) • Bag Unloading Machine for Big-Bag Filling • Automatic Cleaning System that can be integrated into the machine. (With Blowing Nozzle and Vacuum Suction System) • Select ATEX Motors and Electrical Components for Explosive and Flammable Raw Materials. • Pneumatic transfer of the discharged raw material to the silo at the selected address. (Electro-mechanically and automatically with the help of low pressure air can be sent to 1 to 99 silos) • Maintenance platform with ladder and access door • The machine can be manufactured in a single X axis. In addition, according to the condition of the site where it will be installed; It can be manufactured in L type, XY axis, Right or Left Pallet feeding.

With our machines; bags made of PE, PAPER and WOVEN PLASTIC can be emptied.

Our machines are used for processing the following products:

• Plastic granules; (PP/PE /LDPE/HDPE) • Granulated Raw Materials of All Kinds • Granulated Sugar • Powder component products • Rice • Sesame • Pulses Products

Bag Unloading Machine

Our fully automatic standard 25 kg or 50 kg bag unloader unloads granule-filled bags. Pallets can be fed into the elevator manually or automatically from the front or side. After placing the pallet on the elevator; the elevator will lift the pallet upwards and transport it to a mobile gripper shuttle. The integrated grippers will pick up a layer of 5 bags of the pallet and start the unloading process. The shuttle will take the bags grabbed by the grippers to the rotating blades to tear them off and drive them through a unique shaker system to the final bag drop hopper and stop. This unique shaker system will ensure 99.98% emptying of the bags. The product will be collected in the product hopper. After emptying, the shuttle will drop the empty bags into a bag hopper. This bag hopper is connected to a waste bin. Here the operator or other workers can remove the empty bags. In these standard units, the main control cabinet is usually mounted at the front or side of the machine. The HMI touch panel provides a good overview of the unloading process during operation. All stages are displayed on the screen. Are you interested in other products besides 25 kg or 50 kg bag unloading machine?

We can offer different solutions with configurations suitable for your system and process.

Our machines are fully configurable and adaptable according to the customer's wishes and the operation of the process. For possibilities, please contact us for Various Variations.

◆ Do you want to buy a 25 kg or 50 kg bag unloader? ◆ Do you want to automatically store your unloaded products untouched? ◆ Would you like the products you receive in warehouses to be automatically transferred to your machines? ◆ Do you want to automatically receive, stock and transfer a wide variety of products from different warehouses to your machines? ◆ Have you seen our Modular Galvanized Silos that we can offer you for stocking? ◆ Would you like to see the amount of the product you are stocking in the silo and how many kilograms of product are placed in the silo on your computer screen? ◆ Would you like to report how many pallets of raw materials the machine unloads in a day? ◆ Do you need a homogeneous dosing station, no matter how many components you have? ◆ Do you want to dose and mix products with different ingredients that you store? ◆ Would you like us to set up your system to work 24 HOURS a day? ◆ "Human beings make the most mistakes." - "It is human to make mistakes." Do you want to get rid of these mottoes, these clichés? ◆ Would you like to monitor and control your system with your mobile phone by providing remote access while your system is running? ◆ PLEASE contact our experts so that we can offer you the 100% Correct Configurations.

Pneumatic Raw Material Transfer Processes

In pneumatic transfer processes, it is necessary to use a number of standard products from the design and assembly stage due to the ease of material transmission, ease of assembly, static electricity problem, etc. These are mainly; Blowers, Eklüsler, Airlocks, Pipes, Wide Angle elbows, Pipe connection clamps, Three Way Pneumatic valves, Sliding Type Pneumatic Valves, Flex connections and hoses. All mentioned equipments are designed according to DIN standard pipes. We use stainless steel pipes, stainless steel clamps and stainless steel three-way valves to prevent static electrification and hygienic transfer of your products. Pipe diameters vary according to vacuum, pressure and the capacity and flow rate of your process. It has a high selection range according to your process with different sealing elements including EPDM, NBR and rubber for food processes and a variety of different lengths.

Phase Types of Pneumatic Conveying Systems

Pneumatic conveying systems can be generalized under two different headings according to their conveying phases; these are sparse phase and dense phase pneumatic conveying. These conveying phases are distinguished according to how the material is transferred during pneumatic conveying (air conveying). Sparse Phase Pneumatic Conveying Systems Sparse phase pneumatic conveying systems are used to transport granular dry materials from one point to another without allowing them to settle in the pipeline. Bulk materials are transported in suspension with air at low pressure (usually less than 1 bar) and high speed. Sparse phase pneumatic conveying systems are also known as "low pressure systems" because they transport materials at high speed and low pressure. The most important factor in these systems is the conveying speed of the dry material particles. If the particles are transported at too low a velocity, they can settle and accumulate in the pipeline, while particles transported at too high a velocity can be damaged by collision with the pipeline or within the pipeline itself. Sparse phase pneumatic conveying systems can be made in two ways; sparse phase pressure conveying and sparse phase vacuum conveying. Dilute phase air conveying systems are generally used in industrial applications where non-corrosive, low bulk density and durable bulk materials are handled. Examples of dry raw materials transferred by dilute phase conveying are sugar, flour, chemicals, polymers (resins and compounds), calcium carbonate, cement and coal dust.

Intensive Phase Pneumatic Conveying Systems Dense phase pneumatic conveying system is used to transport dry material in pipeline with low speed and high pressure difference. The particles of the bulk material are usually transported in the pipeline at a speed lower than the settling speed and therefore the transfer process is efficient and does not damage the material. Dense phase pneumatic conveying is also called "high pressure conveying" due to the use of high pressure differential. During dense-phase pneumatic conveying, the material can be transported in blocks that completely cover the pipe or in waves. The most important factors in dense-phase pneumatic conveying systems are the type of material being conveyed and the design of the conveying facility. These systems are suitable for transporting abrasive, flammable, brittle and dosed and mixed materials. Dense phase pneumatic conveying systems are divided into dense phase vacuum conveying and dense phase pressure conveying.Yoğun faz havayla taşıma sistemleri; yüksek miktarda malzemeyi, daha uzun boru hatlarında taşıma imkanı verdiği için, çeşitli endüstriyel sektörlerde ve farklı uygulamalarda kullanılır. Yoğun faz sisteminde en çok transfer edilen malzemeler; kum, kireç taşı, gipsiyum, uçucu kül, çimento, kalsiyum karbonat gibi ürünlerdir.

Food Industry Food production is one of the world's largest, most diverse and most important industries. Pneumatic conveying systems meet the high hygiene standards of the food industry, is often preferred because it provides efficient material transfer. A wide variety of food products such as sugar, rice, corn, spices, grains, flour and animal feed can be transported using pneumatic transport mechanisms. Pneumatic conveying systems design and production requires knowledge and attention at every step. We offer turnkey pneumatic conveying systems solutions for this type of Pross.

Chemical Industry The chemical and petrochemical industry uses closed pipelines to transport chemicals from one or more sources to one or more systems is one of the main sectors using pneumatic conveying systems. The use of polymer materials is in vogue, leading petrochemical industries to process large quantities of raw materials (monomers). During the handling of bulk materials in this sector, processes must be carried out carefully and in the healthiest ways to prevent cross-contamination, reduce explosion risks and prevent dust emissions.

Plastic and Polymer Industry The plastics and polymer industries produce and transport a large number of various raw materials. Pneumatic (air) conveying systems; transportation of plastic pellets and powdered materials is one of the most suitable options. Mixing, extrusion and molding in the plastics industry such as extrusion and mixing machines. These processes (extrusion and mixing machines etc.) pneumatic conveying systems are preferred for feeding.

Bulk Raw Material Handling Systems In pneumatic conveying systems, dry materials are not transported by means of fast moving parts as in mechanical conveying systems (belt conveyor, screw conveyor, vibrating conveyor...). This avoids the risk of damage or contamination of the bulk material. Examples of materials transferred by pneumatic conveying systems are sugar, spices, salt, flour, corn, popcorn, coffee beans, sand, limestone, cement, coal, gypsum, plastic pellets, powdered plastic, calcium carbonate.

Pneumatic Conveying System Advantages Pneumatic conveying systems offer many advantages to users: ◆ Pipelines can operate over long distances and can be used both horizontally and vertically. ◆ Since the materials are transported in a closed pipeline, the materials transported in this way remain clean and dust emission to the atmosphere is prevented. ◆ Compared to mechanical conveying systems, pneumatic conveying components are much more compact. Therefore, it can be easily adapted and used in the plant without relocating the existing machines within the plant. ◆ Air transportation systems allow the product to be transported wherever the pipeline can pass. ◆ Pneumatic conveying systems do not take up much space in the plant. ◆ Components such as the blower, pipeline and the unit that feeds the system with material are the few main parts of the pneumatic conveying system. Since all parts can be repaired independently without disrupting the system, the maintenance and repair processes of pneumatic conveying systems are very easy.