AUTOMATION EXPRESS

Dosing and Storage Solutions

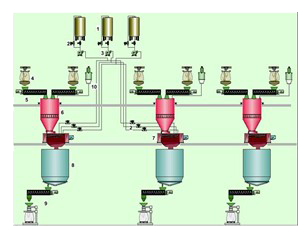

Your raw materials may have a granular component, a powder component or an oil component. Do you want to dose a large number of raw materials? Do you need to mix dosed products? Do you need to store a wide variety of mixed products? Do you want to feed and send your ready products in the warehouse to your machines in the process? Do you want to store your semi-finished goods or final products? Tnm Industrial offers Dosing, Mixing, Storage and Feeding Systems in various sizes and capacities for many product types. With our help, your transactions will definitely run smoothly. Browse our services online.

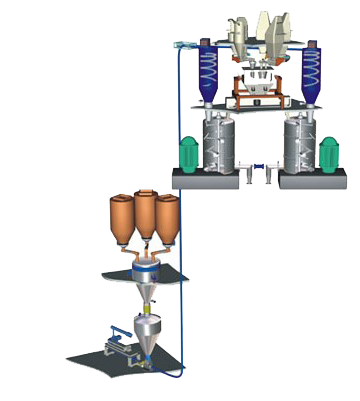

RAW MATERIAL DOSING, STORAGE and SUPPLY SYSTEMS

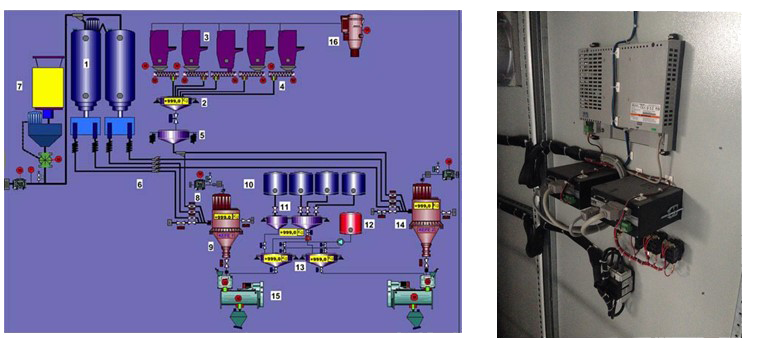

There is a lot of equipment in the process; ◆ Dozers of various types, suitable for process capacity, ◆ Steel construction doser platforms, ◆ Platform for additive raw materials, ◆ Self Crane Pvc and Calcite Discharging Station (Discharging from Big-Bag or 25 Kg. Bag) ◆ Steel raw material Storage Silos from 1m3 - 100m3 volume, ◆ Weigh Bunkers ◆ Mixers ◆ Vertical conveyor elevator and Horizontal conveyor screws, ◆ Liquid dosing units, ◆ Pneumatic conveyor systems, ◆ Electronic filter systems, ◆ Modular Platform and Bunkers on Extruder ◆ Pneumatic covers, on-site auxiliary electrical panels, ◆ Central control panel with PLC and SCADA system,

All Equipments and Units are 100% manufactured in our factory and delivered after assembly. In addition, all silos and process can be designed in ATEX standard. In liquid tanks, the structure can be curved, serpentine and designed according to the desired pressure class.

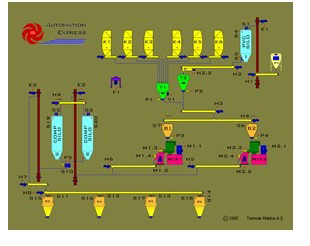

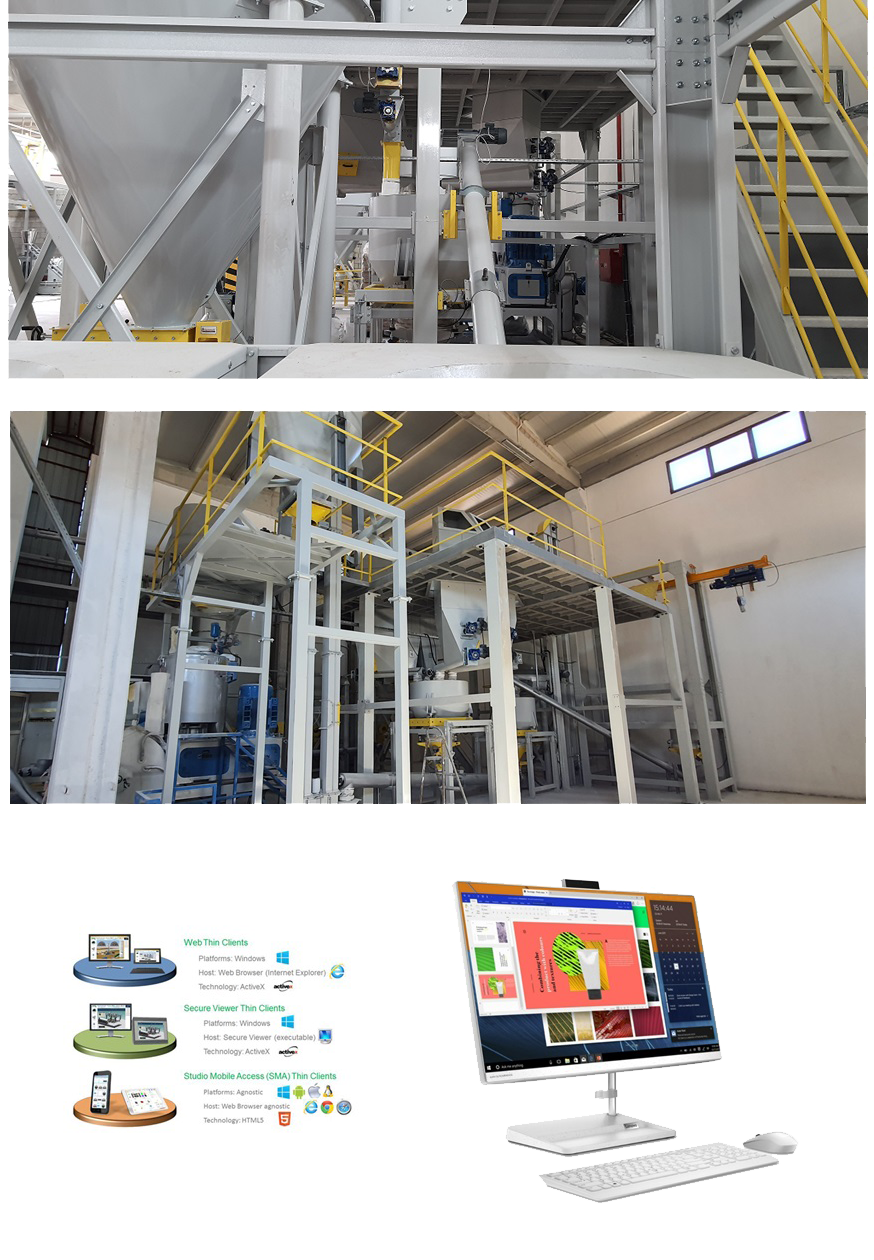

Process Control, Engineering, Manufacturing and Application; No matter which sector you are in, no matter which production you do. If your product consists of a recipe or a mixture, we build your process turnkey from raw materials to semi-finished or finished products. We offer you solutions as Design, Projelandirme, Electrical, Electronic and Mechanical products. Especially in our work for Food, Pharmaceutical, Plastic manufacturers, we use today's technology at the highest level in storage in silos, mechanical powder or liquid transfer, then weighing and dosing according to the recipe. Weighing and Dosing Operations; All the materials that make up your process are weighed with 0.3% precision with the help of loadceller and your mixtures are created according to your production recipe. In addition, we can measure the amount of your raw materials or semi-finished products in continuous continuous type processes, which cannot be discharged and weighed anywhere, while your raw materials or semi-finished products are in a fluid state during transfer with the help of loadceller, magnetic, volumetric or turbine type flowmeters in pipes and flow tanks. For example, a detergent that has a gel-like consistency and is not viscous, grease, oil, sludge, pastry cream. In powder raw materials, this measurement work is done with the help of mechanical conveying. The easiest way to accurately and quickly weigh the raw materials that make up your blends; Stability of the mixing ratios that make up your products ensures the continuity of the standard of your production. It is an accepted fact that raw materials that are more or less than they should be change the quality of the product. Perhaps the tolerance of your work can compensate for these inaccuracies. But what should happen is that, compensated or not, whatever you want to use in your mixes and how much you want to use, you should use the target amount in one go. To achieve this goal and to avoid any kind of inaccurate mixing, more or less, and to use the right methods and tools instead of leaving it to tolerances. Atmospheric Conditions of Time, Temperature, Humidity; If your process works in an atmospheric environment; if the amount of humidity varies according to temperature and time, and different situations can be evaluated differently and change the production program, we can direct your process according to these conditions by keeping these variables conditional. Profiubus/SCADA,PC,Network, TCP/IP İntranet ve İnternet; Your process, production recipe, formulas can be changed by authorized users in the local network with the help of SCADA by authorized users, can be viewed from remote locations by internet browsers, can be designed and commissioned to give Ms Excel printouts. If desired, the system can also communicate with other systems via Profibus.

ZAMANDAN ve ELEKTRİKTEN TASARRUF

In a plant where a mechanical storage and feeding system is installed, the raw material transportation process is both fast and with very low electricity consumption values. Conveying can be either Electro-Mechanical or Fully Pneumatic. Although all the systems and Processes we make have similar types and characteristics, all processes show differences due to regime and ambient conditions. No system is the same as any other Process. For this reason, all software CAD, CAM, PLC, SCADA are applied in our own organization as required by the process and if necessary, in the field trial phase, as a result of the directives from the field operators. All user interfaces used in the processes include PLC and SCADA. These devices necessarily communicate with other users located in the same area. In addition, you can network your process with TCP/IP protocol and intranet solutions. environment, internet and different locations. This way, even if the production center and offices are in two different cities or countries we can connect and share data with each other. Also; ◆ Automatic pallet bag deinking machine ◆ Portable, Speed Controlled Raw Material Feeding Units, ◆ Big-Bag Discharging units, ◆ Big-Bag Filling Stations, ◆ Finished goods loading belts, ◆ Laboratory corner welding and drop test equipment, ◆ Product transport carts, ◆ Pvc profile tilting tables, ◆ Pvc profile gasket mounting apparatus are also included in our product portfolio.

AUTOMATION EXPRESS FEATURES

DOSAGING In industrial processes, finished products are obtained by mixing many raw materials in certain proportions. Automation Express comes into play at this point and undertakes the automatic dosing of raw materials in the desired proportions. The system is designed to require minimum human intervention while performing all these operations. Thanks to the mechanical and electrical control systems, which are fully computerized and simulated, the system performs all these operations quickly and precisely, thus ensuring accuracy and continuity in dosing.

TRANSPORT An economical and long-lasting transportation system is obtained by using horizontal lead screws at all raw material transportation points. The biggest advantages of this system compared to the pneumatic transfer system are that it consumes less electricity, requires very little maintenance, does not cause dust and works quietly. In addition, the need for spare parts is almost negligible, and when a part needs to be replaced, it can be replaced with a new part in a very simple way. Since all extruders are fed with a single motor and a single line, it consumes very little energy compared to the pneumatic system. The line can be easily extended when a new extruder machine is purchased. When buying the machines, you can also buy an absorbent. is no longer necessary. This reduces the initial investment cost to a certain extent.

CARE All vertical and horizontal carriers used in the system are designed in a computerized environment and made suitable for the process, and special type bearings, bearings, reducer motors and spiral screws are used. The biggest advantage of the user in this system is that the bearing system parts in each horizontal carrier spiral are standardized and all parts are compatible with each other. All bearing housings are precision machined on CNC machines. None of the equipment in the machines in the Automation Express system is manufactured in such a way that it can never be disassembled, and all kinds of assembly facilities are applied in the machines or equipment that make up the system in order to carry out technical maintenance that may be required in the future.

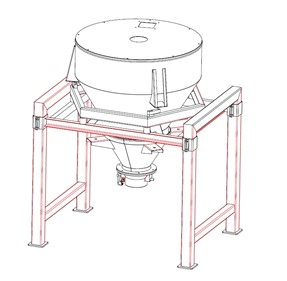

STORAGE The system automatically takes the charged product (COMPOUND) coming out of the mixers and sends it to the compand silos connected diagonally to each other. The silos are manufactured with the utmost care and are absolutely dust-free. In each silo, Pressure Sensor PS, Limit Sensor LS and special type filter mounting points are prepared. In addition, there is a maintenance cover on each silo, a maintenance ladder to descend into the silo (the maintenance cover cannot be opened when the silo is full), a ladder to climb from outside the silo to the silo, and a silo discharge valve under the silo. A special filling path is designed inside the silo so that the charged product is slowly filled into the silo without decomposing in the air. All silo interiors are painted with solvent-free EPOXY paint to ensure a long service life. In the storage section, 2 - 4 - 6 - 8 silos are used to store the charged raw material. resting and cold material flow to extruders. This ensures high production and color quality.

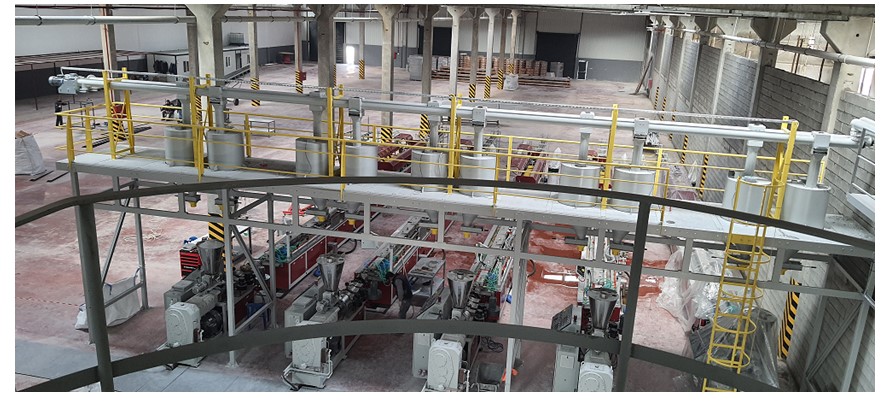

EXTRUDER FEEDING UNIT We've put an extruder on all the extruders in the factory. made of steel construction modular type platform is being built and 2 pieces for each extruder on this platform bunker is mounted. One of the hoppers is used for white compound and the other for colored compound. The bunkers take an average of 500 to 700 kg. of material and continue to feed the extruders for 1 - 2 hours in case of any malfunction or maintenance. Thus, there is no product breakage. A horizontal lead screw is attached to the assembled bunkers. Depending on the condition of the building and the project, the horizontal conveyor screw is fed from the silo by vertical carrier elevators or screws. Thanks to the LS (Limit sensor) in the bunkers, the horizontal conveyor screw and other additional feeders that feed this screw automatically start and stop and fill the bunkers without interruption.

HEALTH Many raw materials used in dosing may contain lead, asbestos etc. substances that threaten human health. Since the system operates in a completely closed circuit, it eliminates many factors that threaten worker health. EARNINGS Thanks to the input information from the machines, the motors start or stop spontaneously. Thus, it does not consume electricity by working unnecessarily. Each machine is activated when it is needed and automatically deactivated when it is no longer needed. Since the automatic dosing system reduces personnel error to zero, it does not allow the formation of incorrectly dosed or mixed raw materials that spoil and go to waste. In this way, every kilogram of raw material purchased takes its place directly on the shelves as a finished product...

ISO REQUIREMENT Automation Express enables your factory to produce at European Standards. Since the system contains extremely advanced technologies, your current quality percentage will increase instantly. Thanks to the central system control mechanism, it is possible to make Daily / Weekly / Monthly reports, to allow the main system screen to be viewed from another desired point, to provide remote access (via TCP-IP or DSL) and to provide instant access to the working information of the factory. The system absorbs 90% of the errors made in a manned factory. Thanks to the automation technology that minimizes the margin of error, the product you manufacture will be manufactured in the same quality every time. The same values will be obtained every time in the tests performed by taking samples from the products manufactured within a year. The system software has the algorithm to detect even situations where the operator gives incorrect commands. For example; new product cannot be sent to the system while there is product in the mixer, and the system cannot be commanded to re-dosing while the hopper on the mixer is full. Many such possible errors are already loaded into the system memory. When such operation orders are given, the system warns the operator by giving alarms and warnings.

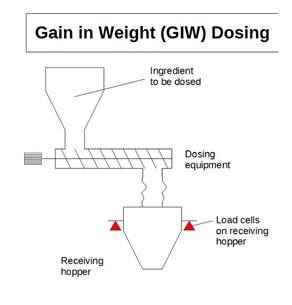

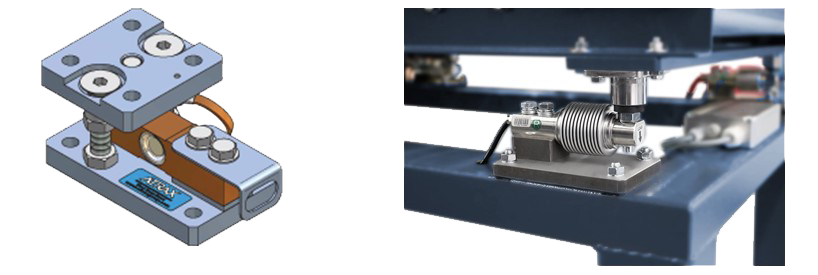

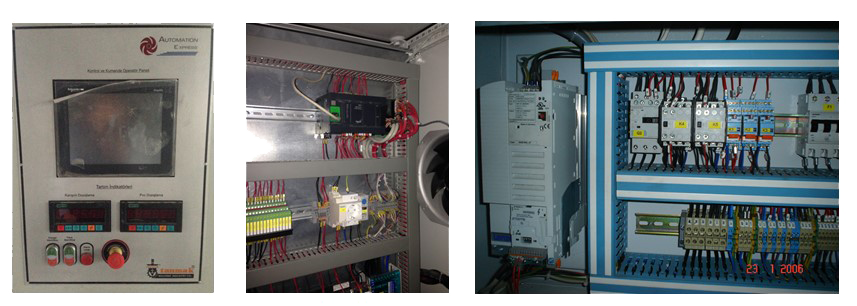

HOW THE SYSTEM WORKS Mechanical DOSERS consist of weighing scales, load cells, horizontal and vertical carriers, main control panel, PLC, Scada, Indicators, switchgear, various sensors, pneumatic piston valves, level control systems and computer. After the values entered on the PC screen (prescription), the system takes the desired material as much as desired. The raw material values automatically poured into the weighing scales are transmitted to the PLC via load cells. When the PLC reaches the value entered on the SCADA screen, it automatically cuts off the material flow and starts to receive the next material. When all raw material intake processes are completed, the necessary mechanical conveyors are activated and then the pneumatic actuators coupled under the load scales are opened and the dosed raw materials are discharged from the scale. Thanks to the mechanical conveyors, the raw material is delivered directly to the mixer. This process cycle is repeated automatically for the period entered into the system.

SENSITIVITY Basic factors determining the precision of dosing systems; Precise mechanical manufacturing, precise assembly and the sensitivity of the electronic system. The sensitivity rate of the weighing units on prescription basis is ±300gr. Mechanical Design: The system is specially designed according to the fluidity and density of the raw materials. The mechanical structure of all raw material dosers varies according to the type of material. Automation Express compensates for varying fluidity levels with its special type mixing mechanism and constant material pressure plates. Load cells are selected according to the capacity of the system and mounted on steel construction chassis with specially developed mounting apparatus. to the mounting points on the system. In processes where the measuring range of the system is very different, raw materials makes dosing by weighing on scales.

Electronic Design: Input information collected from the load cells used in the system is directly transmitted to the PLC. Load-Cells used in the system are manufactured with the latest technology and perform extremely stable weighing. The information received from the Load-Cells is transmitted to the PLC and the weighing process is realized. The values processed in the PLC are instantly reflected on the SCADA screen. Thus, problems such as slowdown, delay and instability in classical systems are not experienced. Lower Tolerance Control: It is activated when the system receives less material than the lower tolerance value entered by the user. This usually occurs when there is vibration on the scale. Automation Express continues to receive the material until it reaches the set value, ensuring that the material is received in full. The system warns the operator when it cannot take the material into the weighing hopper or when it takes the material too slowly. If the operator ignores the warning, the software stops dosing and gives an alarm. After the error is eliminated, the system is configured to continue working from where it left off.

Upper Tolerance Control: It is activated if the system makes an intake out of tolerance above the required amount. The system warns the operator and goes into a waiting state. The operator decides whether to continue or not according to the status of the excess intake amount. Concussion Control: The jolt algorithm in Automation Express recognizes jolts and ensures that the system is not affected by these jolts. Especially the vibrations caused by mixers sharing the same concrete floor with the dosing system or forklifts traveling in the working area can create instability in weighing. It is a known fact that mixers that pull excessive load at the moment of take-off make a high degree of shaking. Thanks to the jolt control algorithm that eliminates these jolts, the system continues weighing and therefore production without being affected in any way by the jolts. Total (cheksum) control of the weighbridge: Automation Express checks whether the materials have been received correctly by checking the scale total after each material purchase. Flow Control Material flow control continuously checks the flow of the material. If the flow falls below the specified value, the system warns audibly and visually that the material is not flowing.

SYSTEM FUNCTIONS

◆ Ability to make between 1 - 100 prescriptions, ◆ Log keeping ◆ Thanks to the encryption system, unauthorized access to the system preventing people from interfering, ◆ Reporting consumption values, ◆ ALARM in case of interruption of material intake or material supply, ◆ Alarm list of devices in the system, ◆ Failure reporting, ◆ Continuous system operation control with continuously communicating internal and external PLCs, ◆ Digital I/Os, ◆ Possibility for the quality control specialist or production manager to change the recipe from their own room, ◆ Ability to continue from where it left off in power outages, ◆ PLC manufactured with the latest technology, thanks to the use of ORIGINAL SCADA software completely REGISTERED on your behalf lock-up and slowdown problems caused by "PLC - NON-ORIGINAL SCADA" communication in classical systems; you will not encounter in Automation Express...

SAFETY The scale maximum protection prevents the load to be taken to the scale more than a certain value. The ability to enter and change special tolerance values offered by Automation Express ensures that the same amount of material is always received. Shake control algorithms ensure that the system always receives material in a stable way and does not allow incorrect mixing. All electric motors in the system are also protected by phase protection switches, motor protection switches and speed guards. CONTINUITY In case of any problem with the PLC or Operator Panel in the system, the whole unit is also designed for manual dosing. Thus, all additives can be taken and dosed manually by the operator. Each machine in the system can be controlled manually. In this way, the uninterrupted operation of the factory is guaranteed until the main PLC system is re-commissioned. In addition, after the entire automation system is commissioned, the system SETUP file of the existing software is prepared and given to the user in SSD. When the computer that breaks down for any reason is reinstalled or replaced with a new one, the entire system can be loaded instantly using this SETUP SSD and the facility can be put into operation. ELECTRICITY CUTS The system is protected from the factory mains by an online UPS and mains filter. When the power goes out, the software recognizes this and goes into standby mode. It continues to keep the current step in its memory. As soon as the mains voltage is restored, it waits for the operator to give the START command for safety reasons. As soon as it receives the start command, it continues the dosing work from where it left off.

AUTOMATION EXPRESS CONTROLS Automatic speed controller Automatic closing Silo level control Material flow control Sub-tolerance control Upper tolerance control Concussion control Weighbridge total control

REPORTING Detailed Report Daily Report Monthly Report Annual Report Prescription Based Production Report To be able to get Graphic Printouts of Reports, transfer to Microsoft Excel

REMOTE DATA ACCESS It provides access to the data produced by the system over the factory network and over the internet. It is possible to access all features of the program, visual elements (silo levels, status of machines), all data over your corporate network and the internet. For this purpose, additional applications (ASP Server, SQL Server) are installed on the system computer and your system is made suitable for this access.

WORK WITH MULTIPLE USERS The program can work as multi-level and multi-user. Multiple users can access the system at the same time and make changes or observe the system according to the rights granted to them. For example, while the operator is only authorized to run, the production supervisor can be authorized to change the recipe and report. PROJECTING Mevcut ya da yeni kurulacak fabrikanıza haiz çözümler firmamız tarafından sağlanacak olup, bina ölçüleriniz ve makina yerleşim durumları tarafımıza ulaştıktan sonra makine mühendislerimiz tarafından projelendirme yapılarak proje çıktıları bilginize sunulacaktır.

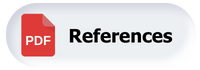

1. ASSEMBLY After the transportation of the products, which are meticulously manufactured according to the project, to the place where the assembly will be made, they are meticulously assembled by Tanmak Makina's expert assembly team in the field. Since the entire production is manufactured with millimeter precision thanks to computer-aided design during the manufacturing phase, no problems are encountered during assembly. In this way, even the smallest platform and equipment delivered to the installation site is not subjected to reapplication, cutting-welding etc. applications.

2. HOW THE SYSTEM WORKS There is a separate storage bunker for each additive. Bunkers are specially manufactured to prevent sticking and ensure fluidity. All bunkers are Electro-Static painted inside and outside. After the bunkers are filled with the relevant substance, when the system is started, the additives are taken into the scale bunker in order according to the recipe information previously loaded into the memory. Product feed screw reducers are equipped with a speed control device (inverter) for precise weighing finalization. The required flow slope is provided to ensure that no material remains in the scale and is also reinforced with a vibrator. The material status in the scale will be monitored on the indicators and the weight information will be transferred to the PLC at the same time. All field control operations of the dosing system will be carried out by special application software to be written via PLC. Manual Operation In the system, in case of computer and operator panel failure or if desired, it is possible to dose by pressing the doser buttons on the control panel and observing the scale indicator. Automatic Operation The system has two different levels of operation, automatic via computer and manual via panel. In case of failure in the computer system, the working positions of the field will be monitored through the Operator Panel mounted on the control panel. In case of malfunctions and alarms occurring in the system, a light and audible alarm will be given and the operator will be warned. The system will automatically weigh and dose the desired amount of material in the desired order in accordance with the recipe entered in its memory. Fully Automatic Operation Fully automatic control and monitoring of the system is done via computer. Prescription recording and reporting procedures will be carried out with the Central Prescription Recording and Reporting Program. Prescription records will be made via computer and will be restored to the system when requested. Prescription production processes will also be done via computer. The report of each completed prescription will be saved in the memory and production or consumption reports can be obtained on a system basis or in total between the desired dates. The software runs under Windows. It utilizes all the possibilities and flexibilities of the Windows environment. All parameters and commands can be accessed via menus, making it easy to use and reducing operator errors. Reçete Üretim Sisteminin Temel Özellikleri • The recipe to be produced is selected from the Operator Panel and production is started by entering the desired quantity and batch number into the system. The desired quantity of the same recipe can be automatically produced consecutively in batches. • If the flow of goods is interrupted during raw material intake, it warns the operator by giving a 'Flow Alarm'. • It gives 'Tolerance Alarm' when there is excess material intake out of tolerance. • Produced recipe quantities and Consumed raw material quantities are saved in the memory. • Prescription entries and parameter entries are password protected. This prevents unauthorized persons from changing parameters.

3. FEEDING UNIT System Description The system; after taking the raw materials to the warehouses and weighing the recipe entered on the Scada screen precisely and sending it to the mixer, the storage of the resulting mixture and automatic feeding to the extruders is controlled by the mechanical equipment in the field in the Digital Environment. System Operation The main raw material, PVC silo, is designed with a capacity of approximately 30 to 50 tons. Grids and magnets are placed at the material pouring points of the silos to prevent foreign materials from entering the system. Pneumatic conveying is not used anywhere in the system.

Extruder Feeding Unit and Technical Specifications The platform on the extruder used in the system is CAD designed and completely Electro-Static painted. It will be assembled bolted in place in the field. It is designed with extremely high mechanical strength. All mechanical components that make up the platform will be shipped to your site as Electro-Static painted. There are 2 raw material bunkers per extruder on the platform and colored and white feeding screws are positioned on the platform. There is a valve and magnet box between the auger outlet and the raw material hopper. In this way, any metal parts in the system will not be allowed to pass into the bunker. There is also a valve at the bunker outlets. Thanks to the sensors on the bunker, the bunker automatically requests the raw material from the system.